Nokeval’s NSnappy measuring devices and digital self-monitoring service meet the calibration requirements laid down in EU Regulation 37/2005

Commission Regulation No 37/2005 on the monitoring of temperatures in the means of transport, warehousing and storage of quick-frozen foodstuffs intended for human consumption sets a clear requirement for measuring devices. The standards referred to in the Regulation impose a requirement concerning regular calibration. The Regulation is the strongest of the European Union’s stipulations, it is regarded as legislation that is directly binding to Member States, and it is in effect as is in all EU Member States.

Commission Regulation 37/2005 demands measuring devices to meet the requirements of standards EN 12830, EN 13485 and EN 13486. The standard sets various requirements on measuring devices with regard to measuring accuracy, reaction speed and other properties. Section 9 of standard EN 13485 on regular verification requires cold space measuring devices that are in operation to be regularly verified, i.e. calibrated, according to standard EN 13486.

In other words, the EU Regulation requires temperature measuring devices to be compliant with the relevant standards and their measuring accuracy to be regularly checked by means of calibration.

Nokeval’s NSnappy measuring devices and digital self-monitoring services are compliant with the standards

Nokeval’s NSnappy measuring devices and NSnappy self-monitoring service meet all requirements set by the three necessary standards, such as the requirements on accuracy and reaction speed.

Nokeval’s NSure lifecycle service ensures regular calibrations without equipment downtime

The NSure lifecycle service, which is part of Nokeval’s NSnappy measuring devices, ensures regular and easy calibrations for measuring devices.

Customers are provided with calibrated and adjusted measuring devices by post automatically and regularly. The measuring devices are very easy install, and the used ones can be returned to Nokeval for recalibration in the same package. Nokeval ensures operations according to the principles of responsible and sustainable development by providing a superior calibration service that is both cost efficient and environmentally friendly.

The NSure lifecycle service guarantees reliable operation, timely maintenance and equipment covered by a continuous warranty without any downtime.

A calibration certificate is always available

The calibration certificates for Nokeval’s measuring devices can be found in the NSnappy self-monitoring service, which means that their compliance can be effortlessly indicated to a health inspector.

FAQ – frequently asked questions

Who are and are not affected by EU Regulation 37/2005

The Regulation applies to temperature monitoring during the transport, warehousing and storage of quick-frozen foodstuffs.

It does not apply to small devices in retail spaces or small storage spaces for frozen goods (max. 10 cubic meters in Finland).

Why is calibration so important and what benefits does it yield?

The accuracy of temperature measuring devices is a key factor in operating environments that involve the transport, warehousing or storage of frozen foodstuffs. Erroneous measurements can lead to production errors, deteriorated quality and food safety risks. This is why it is important that the temperature measuring devices are accurately calibrated and that their measurements are reliable. Calibration is an essential process in making sure that temperature measuring devices work accurately and reliably.

Precise and reliable temperature measuring devices ensure that the refrigeration equipment works optimally at the correct temperature and according to the instructions of the manufacturer. The correct temperature secures the maximum shelf life of valuable foodstuffs according to the promises of the product manufacturers. In addition to this, refrigeration devices that operate at the correct temperature save energy and last longer without failures. This saves energy directly as well as reduces maintenance costs and the need to invest in new refrigeration equipment.

How do measuring devices need to be inspected and calibrated?

Standards EN 13485 and EN 13486 determine how measuring devices must be calibrated. Section 5.3.1 of standard EN 13485 indicates the testing method for determining the temperature measurement error.

The standard necessitates calibration at several different temperature points. The measuring cycle is as follows: alternated between 0%, 50% and 100% of the measuring range or at the fixed temperatures -30°C, 0°C and +30°C, if the measuring range is wider. Each temperature must be provided with at least an hour to stabilize.

Replacing power sources does not equate to calibration. The batteries in transmitters are wearing parts, which are used to collect measuring data and transmit it online. Battery replacement has nothing to do with calibration.

Can I check the accuracy of a measuring device myself?

You can perform the inspection yourself if you are sufficiently knowledgeable about measuring technology and have access to approved measuring equipment. In practice, the process is slow and difficult. Moreover, the calibration requires a reference device that has been calibrated in a traceable manner and is one category more accurate than the measuring device to be calibrated. The reference meter must also be calibrated regularly and have a traceable calibration certificate that covers the entire measured area.

Practically speaking, it is never sensible or cost efficient to perform the calibration independently. Instead, the surest way is to use products from a manufacturer that has taken the necessity of regular inspections into account in the design phase.

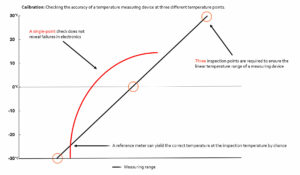

Why is it not enough to use the reference meter for a check at a single temperature?

It is not possible to reliably detect measuring device failures at a single reference temperature, as the transmitter may accidentally show the correct reading at the inspection temperature, even though the error at other temperatures is considerable. For this reason, at least three inspection points are required to make sure that the measuring device operates correctly and measures accurately across the entire range.

In order to meet the calibration requirements, Nokeval developed the unique NSure lifecycle service to verify the accuracy of IoT temperature measurement devices on a regular basis. The service, which is based on replacement modules and provides automatic calibrations ensures that the operation of measuring devices is never interrupted.

Why does using the reference meter for a check at a single temperature not meet the inspection requirements?

The accuracy of the reference device must be better than that of the measuring point being checked. A single-point reference measurement cannot ensure accuracy at other temperatures. The measuring device may display the correct temperature at a single point and the wrong one at every other point. Probability cannot be the starting point for maintaining accuracy. Instead, accuracy must be demonstrated at multiple points (standards EN 13485 and EN 13486).

Are there self-calibrating devices?

Manufacturers may claim that their devices are self-calibrating even though they do not meet the calibration requirement of the relevant regulation and legislation.

Is calibration mandatory?

The calibration of temperature measurement devices is not voluntary. It is based on the applicable EU Regulation and the standards to which it refers. The EU Regulation 37/2005 lays down requirements for equipment accuracy and calibration based on the relevant standards. The calibration process is a critical part of quality assurance and ensures that the temperature measuring devices operate reliably and continuously to ensure food safety.

Checking the calibration of measuring devices is one of the food control measures carried out by the health inspector.

More information: Commission Regulation (EC) No 37/2005